Laser Marking for Traceability:

How to Mark Parts Precisely even within Limited Space

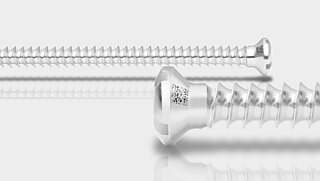

Due to traceability reasons, many parts and products have to be marked with codes. Finding room on a product to place traceability content is often a challenge. Manufacturers and designers tend to use every available space on the part to squeeze all tracking information required.

The marked content, such as the lot number, serial numbers, and a 2D code have to be readable by machines and humans. Sizing down the content is not always desirable, particularly with data matrix codes that require a minimum size as they need to be read by most commercial readers.

How laser-integrated vision ensures precise mark alignment and high-quality marking

With limited space, the alignment of the mark can be a challenge as some of it may not fully land on the part. These slipups can look innocuous but could have a direct negative impact on the product’s workmanship.

To address these challenges, vision technology like IMP (Intelligent Mark Positioning) – basis of the vision-assisted laser marking process HELP (Holistic Enhanced Laser Process) – offers laser-integrated validation tools: Tools that validate the part identity and automatically align the traceability content to the part. Often, parts from the same family, that can only be differentiated by a hole size or a part length, are easily confused by operators. Validating the part identity adds a layer of safety that prevents the wrong part from being laser marked. A mark alignment feature compensates for those situations where the part is not properly seated in its fixture and aligns the mark to the part.

The three steps of a vision-assisted laser marking process

1. Pre-mark verification

Part validation: Validates correct part and prevents marking of wrong parts.

Pre-mark verification: Confirms that only unmarked parts are being processed.

Mark alignment: Aligns the mark relative to the position of the to-be-marked part.

2. Laser marking

3. Post-mark verification

Mark verification: Validates correct placement of markings (position, alignment, size).

Optical Character Verification (OCV): Validates that marked character matches expected content.

2D code validation and code reading: Reads the contents of 1D/2D codes and compares the results to the expected content. A classification of the code into quality classes is possible.